PRODUCT

製品案内

Custom-made products that meet customer requirements.

Topsystem’s manufacturing is an integrated system of custom-made products. We are capable of manufacturing a variety of equipment such as preparation equipment, culture equipment, inactivation equipment, and various plant units.

Gallery of Delivered Products

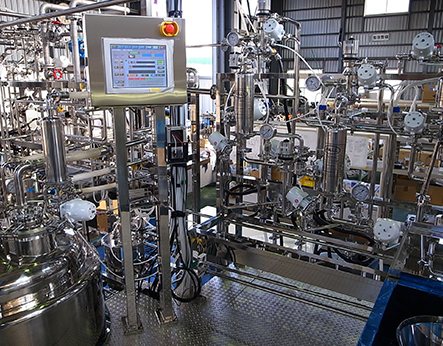

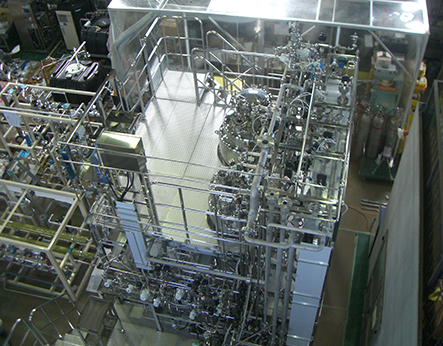

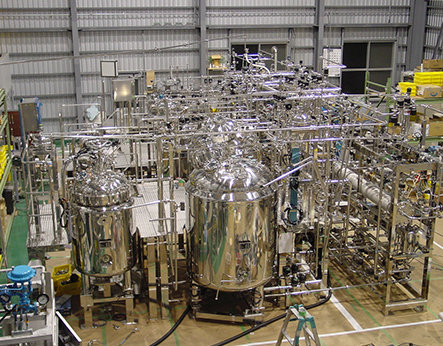

Preparation Equipment

A one-stop system response for various pharmaceutical equipment.

This is a pharmaceutical manufacturing facility for vaccines, anticancer drugs, injectable drugs, and topical drugs such as eye drops, etc. We focus on operability and maintainability based on 3D design. To meet our customers’ requirements, we handle design, manufacturing, and validation in an integrated manner.

Features・Specifications

- Mini-plant consisting of basic components

(vessel, piping, filters, etc.). - C/SIP, preparation process, aseptic filtration, integrity test are available.

- PLC/SCADA control is available.

- Data integrity is available.

- GMP and PIC/S compliance is available.

Inactivation Equipment

Responding to customer needs with our proprietary inactivation equipment

In pharmaceutical manufacturing facilities, post-production wastewater and wastewater inside the equipment must undergo final treatment according to the destination of discharge, such as sewers or rivers. Inactivation equipment is a skid that kills (inactivates) pathogens such as microorganisms contained in wastewater using heat, chemicals, or other methods unique to Topsystem before discharging the wastewater.

Features・Specifications

- Propose inactivation methods that meet customer requirements.

- Both continuous and batch systems can be designed to save energy by taking into account the restrictions on the amount of water received and the amount of wastewater discharged.

- We provide total engineering from hardware design to overall control system.

Local Cooler Units・

Sanitary Heat Exchangers

Proposal for a compact unit incorporating a sanitary heat exchanger

This compact and sanitary unit can be used for cooling water for injection and preparation water. We can also offer local cooler units incorporating our own heat exchanger “Gekisou-kun” (Patent No. 5047251, 2011), which was created through repeated performance and durability tests and improvements, according to your specifications.

Features・Specifications

Local Cooler Units

- Multi-layered tubing allows for a total length of 650mm

(unit outline 650×650×1700) - Air filter can be installed inline if PS line is available for utility.

- Equipped with a conductivity meter as a standard feature to check water quality before supply (can also be used for preparation water and filter wetting).

Sanitary Heat Exchangers

- The sloped tube prevents liquid pooling and is very hygienic.

- The structure absorbs expansion due to heat, enabling cost reduction.

Residual Liquid Collection Systems

Realization of a single system unit for zero residual liquid in filtration

Our self-developed system reduces the loss of liquid during filtration to the utmost limit. In the piping path from the preparation tank to the filtration filter, a stock tank is placed in the upper section just before the primary side of the filter to prevent the possibility of bypassing the pumped gas due to pressure loss caused by the filtration of the filter element. By temporarily stocking the stock tank with liquid and pumping it again, all the liquid on the primary side of the filter is filtered.

Features・Specifications

- In-house test results show a reduction of approximately 1 liter of chemical loss in 10 meter of 1S sized piping.

- Patent obtained(Patent No. 6279359, 2018).

- Realized a single filtration system unit

(filter unit near the filling machine).

Products From Overseas

Introducing products from around the world that are highly regarded in the field of pharmaceuticals

MAVAG: Agitators made in Switzerland

MAVAG’s magnetic agitators are suitable for homogenization, mixing and dissolution, and are widely used in the fields of pharmaceuticals, biopharmaceuticals, foods, beverages and fine chemicals.

G HWA: ASME BPE standard fittings made in Thailand

G HWA’s fittings are compliant with ASME BPE standards and have a wide range of products manufactured under strict quality control in Thailand.

DonadonSDD: Rupture discs and safety valves made in Italy

DonadonSDD manufactures and sells high quality safety products and equipment for industrial plants, including disc holders and rupture discs, associated rupture indicators, explosion vents and safety valves. These products are produced with a high level of technology and are suitable for use in pharmaceutical and other manufacturing fields.

PTFX: flexible hoses for plants made in the UK

Puresil-Techniflex (PTFX) provides high quality, hygienic, high purity process hoses, valves and tubing components to a variety of industries including pharmaceutical, biotechnology and chemical. Pharmaceutical and biotechnology: high-purity smooth-bore silicone rubber and PTFE-lined process hoses, available in a variety of connection sizes and formats.

LABOM: pressure gauges, thermometers and level gauges made in Germany

LABOM’s pressure gauges, thermometers and level gauges are applied to process systems in various industries such as pharmaceutical, biotechnology and chemical. These hygienic instruments are manufactured according to GMP guidelines and comply with FDA (Food and Drug Administration) and EHEDG (European Hygienic Engineering and Design Group) standards.